Advantages of 3D CAD Design Services

Using CAD design in the manufacturing process is very extensive and can’t be stressed enough. Construction companies have turned to this service for their benefit, whether for small operations or large operations.

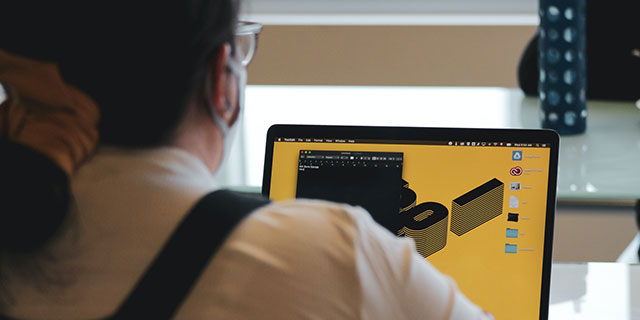

Computer-aided design has made work more accessible in 3D printing and construction. It has software that allows 3D solid and surface modeling. You can view products from different angles inside and out. That is, CAD design can rotate it in three dimensions.

With manufacturing companies competing on producing the best product and increasing costs, the greater importance of using CAD designs to create prototypes reduces costs. It increases efficiency when making the final product.

Let’s learn the importance of 3D CAD design;

1. Improved visualization

With CAD design, it helps create a prototype of the final product. With the prototype in existence, companies can visualize the final product better. It is because they can make changes and clear errors included in the design.

The clients have a better view of what they will be receiving and participate during changes and analysis of the product design. Clients and manufacturers can understand and interpret the design in a 3D model, make intelligent decisions, and forecast the final product.

2. Improves output

Before introducing the 3D design, people used to make prototypes by themselves. Still, people can use this design and create an excellent and flawless prototype with a few errors with CAD. This design improves product formation and reduces the tedious part of the construction.

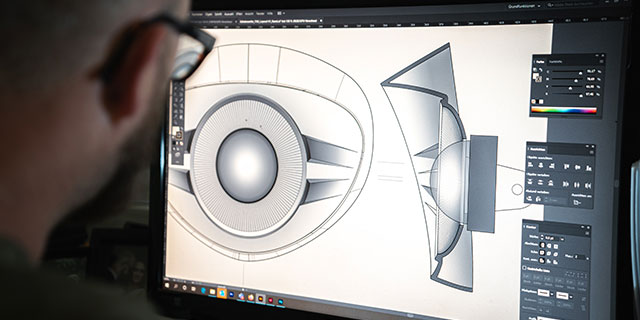

It helps the designer visualize the parts of the product in 3D and correct any errors if required before the construction of the final product begins.

3. Simplifies the design

CAD designs provide the simplest method to create a user-friendly format that ensures every piece of information is in the prototype. In oil manufacturing companies, oil piping becomes a problem when trying to fit them in the sketches.

The design’s capabilities ensure that the plan provides complete and well-designed 3D pipes set up appropriately and with the required connections in place. Parameters such as diameter, length, and pressure are all included in this software to ensure component show their characteristics as they should in the final product.

4. Helps avoid mistakes

With a 3D design to create a prototype, it is easier to note the mistakes made during the procedure and correct them appropriately before beginning the construction of the end product. This design helps you to test for strength, stress, and tolerance.

It saves on costs and ensures the product is perfect once construction has started since it passed the tests.

5. Increases productivity

The 3D design has become a more straightforward version in creating and testing procedures for use. While using 2D CAD requires more evaluation, 3D design can quickly extract information and create a method in a short time.

3D CAD parts of a product can be separated and tested individually without altering other features in the design. This software helps visualize the product how it will by giving it animation and provide modifications where they are required.

These are but a few advantages. This software is straightforward to use and has helped many in reducing costs and time. It can help you improve every stage, from the concept to the final product.