Complete Prototype Services-Modelling On-The-Run

Complete Prototype services are getting a lot of popularity these days. And it is due, not only to the benefits of 3D printing in these organizations but also to the fact that it truly constitutes an alternative that promotes innovation and competitiveness.

Among the benefits of 3D printing to companies that have already adopted this technology, perhaps the most notable may be the ability to manufacture low-volume products, in single-unit batches, at very low costs. This allows companies to be more efficient in the use of their resources and raw materials.

Indeed, 3D printing makes it possible to integrate functionality and intelligence, to design and manufacture increasingly complex products, at no additional cost.

What are the benefits of complete prototype services?

1. Individualization:

3D printing makes it possible to manufacture customized products according to the geometry that best suits each one of them. And it does so under favourable economic conditions for both the company and the customers.

2. Revolution in healthcare systems:

Thanks to 3D printing, surgical planning processes are optimized. Modern 3D technology, capable of producing highly valuable bone replicas when planning the intervention or explaining it to patients in advance.

Also, 3D technology is increasingly advanced in the field of medicine. The specific tooling or the personalized prostheses manufactured by 3D printing have already made their way and shortly, it is expected to achieve organs designed for each patient, quickly and safely.

3. Risk analysis:

This novel technology allows the development of scale models to measure risks caused by natural disasters. And also, in the event of these, manufacture necessary parts to attend to the emergency quickly.

4. Functionality:

There is more to product design than shape. Whether this force, resistance to deformation, providing insulation, avoiding exposure to electric shock, or, conversely, conducting electricity, you expect them to do so efficiently.

With 3D printing, it is possible to evaluate the functionality from the first unit produced, and you should not wait to have batches of thousands, and a series of test stages to verify it.

Also, with the development of the materials used, it is increasingly possible to achieve the functionalities that are sought.

5. Sustainability:

3D printing can be used to reduce the life cycle and environmental impact of products. First of all, 3D printing processes use only the necessary material, as opposed to machining which produces a fair amount of waste.

But there are many ways you can contribute towards sustainability. For example, it can help to reduce fuel consumption in the automotive and aerospace fields, thanks to the optimized design.

Today, there is a wide variety of sectors in which CAD is used on a very regular basis, especially in engineering, civil, or aeronautics, but it is also used by architects or the automotive industry, among others.

This technology allows the streamlining of work, automating the manual processes of the product design process, reducing errors, gaining speed, and increasing quality.

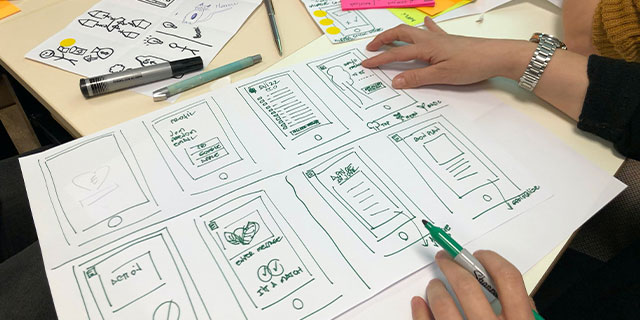

With this, companies thus achieve greater efficiency and productivity, since it allows the final product to be visualized in advance and also to play interactively with different designs, without the need to create a large number of prototypes.

Complete Prototype Services (CPS), is one of the fastest-growing companies that can produce workable prototypes and tooling for the consumer goods, automotive, defense, and medical industries.