5 ways 3D Printing Designs is affecting the design industry

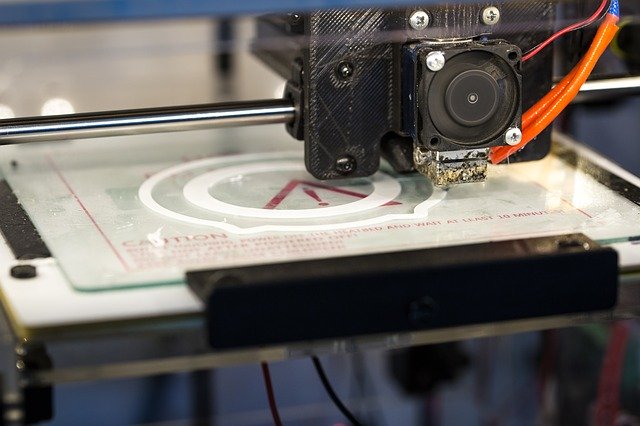

3D printing designs have gained widespread popularity over the years. It makes use of computer-aided design to manufacture three-dimensional objects. This is achieved through layering many materials such as plastic.

Companies are using 3D printing to produce their designs

Traditionally, companies send out product designs to manufacturers with specific details. Then, they wait for the products to be shipped back to them. However, nowadays, 3D printing have made the process so much easier.

With a 3D printer, the process is cut short and product designers can simply use computer-aided design (CAD) software to design and produce the products without going all through different kinds of trouble.

This significantly boosts design efficiency and product manufacturing. Thus, we can expect more companies to come up with designs at a faster pace than usual.

Boom of open-source designs

Everyone can own a 3D printer at the comfort of their homes. You can print virtually everything in 3D. However, you need a CAD software to design anything you’d like to print in 3D.

Currently, 3D manufacturers sell their designs to other companies, individuals, and others for a fee. However, there are some communities that give out rights to open-source designs or charge a way lower price for their designs.

In the future, as 3D printing becomes more widely popular, we can expect to see more creatives share rights to their open-source designs. Furthermore, we also expect more people to learn the basics of 3D printing. Thus, adding more creatives to the designer community.

Design flexibility

CAD is a flexible platform designers can use. Most problems regarding design involved limitations in manufacturing. With a CAD, this limitation is significantly reduced. For instance, without CAD, it would be difficult to manufacture complex geometries, intricate shapes and patterns.

Furthermore, 3D printing designs allow products to be manufactured in one piece instead of different parts. This makes both design and manufacturing more efficient and fast-paced.

Increased design customization

Thanks to CAD software, everyone can take a shot at becoming a product designer. Thus, it accounts for increased customization of product designs. Designers and manufacturers no longer have to rely on high-volume productions. They are now able to customize designs for smaller populations or markets.

Less errors in the production phase

3D printing designs have made it possible to try out different CADs without too much costly repercussions. Designers now have more room to experiment and play around with the design while still remaining to be cost-efficient by resolving the common 3d printing issues in the first place.

Furthermore, it doesn’t take much time to make alterations with the initial design. Thus, designers have the freedom to be more meticulous about design. This allows less room for mistakes in the production phase.

It’s without a doubt that 3D printing has changed and continues to change how brands and companies design their products. In the next decade, we can only expect 3D printing to be a mainstay in the design industry as more companies and creatives know more about it.