The Role of Laser Cutters in Rapid Prototyping – Best Laser Cutting Prototyping Innovation

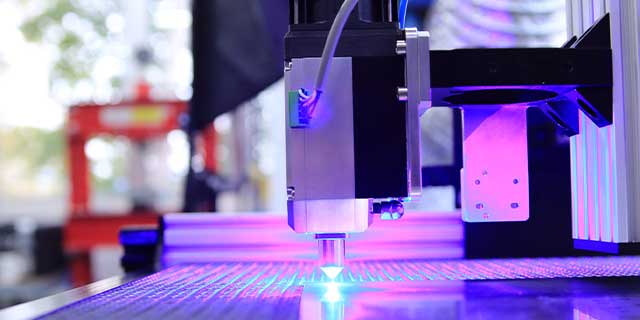

As far as industrial designing is concerned, laser cutting prototyping is incredibly essential. Due to its capacity to produce smooth cutting edges, laser cutting is very valuable, especially for aerospace technology. Laser cutters use a heavy laser to cut various materials. A Laser cutter is a brilliant tool for cutting a wide range of materials. Furthermore, laser cutting in rapid prototypes allows for faster turnaround, the creation of sophisticated designs, shapes, and precise dimensions that were previously impossible to achieve about decades back. With recent laser cutting techniques, a CAD database pattern may be converted into structural sheet metal software without error and with very little human work. Both engravers and Laser cutters are becoming more and more significant in the rapid production whereby performing an important role in product prototyping. This allows designers, makers, manufacturers, and others to see a product in progress that nearly matches the finished result.

The Role of Laser Cutting Prototyping

When it comes to developing a product and gaining finance, it’s vital to start with a prototype. A prototype may not be perfect but should accurately represent the potential of a final product. This can be challenging when the product hasn’t been funded yet. One of the simplest and fastest ways to quickly prototype an item before committing to a larger investment in the services of Laser cutting.

With Laser Cutting There is No Need for Dies

Traditional manufacturing methods typically necessitate the creation of a die, or mold, which is then utilized to make the final product. Laser cutting prototyping, on the other hand, does not need this. Rather, it relies on a computer program to cut the metal to the desired shape. This implies that a business doesn’t have to spend money on a die that would only be utilized one or two times. It also greatly streamlines the process, lowering the period required for manufacture.

Laser Cutting Is Cost-Efficient

Laser cutting is more cost-efficient than other methods for a limited manufacturing run. This is because other methods, such as rotary die-cutting, must be used for large volumes; the more the production volume, the more they are cost-effective. Meanwhile, laser cutting can be ordered piece by piece, based on the budget of the company.

Laser Cutting is Easily Customized

Prototyping entails making changes to the product being created in a haste. Investors may want to see certain possibilities, or the original prototypes may need to be tweaked to make them more appealing. Instead of needing to go back to the drawing board, a laser cutting product allows the prototype to be updated in minutes. This is because the entire process is digital until the final product is created.

Laser Cutting is Very Precise

Laser cutting is one of the most precise technologies available. Laser cutting happens to be essentially the most directed CNC which can cut to extremely tight tolerances; while it isn’t ideal for big production runs, it may produce excellent prototypes. An accurate, high-quality prototype is precisely what a company will require to both seek investors and test its ideas.

Although laser cutting service is still costly, a series of prototypes is unlikely to be prohibitively expensive. You can simply change your prototypes, examine them out, and adjust their builds using laser cutting. You can as well do it without spending a lot of money.

Advantages of Laser Cutters in Rapid Prototyping

Lesser Lead Time

Laser cutting is well-known for its ability to precisely cut metal at high speeds. Laser cutters can cut metals that are less than 3/8″ thick relatively quickly. Cutting time increases when working with durable materials, but still functions rapidly. Laser-cutting prototyping is well suited for both small and large-scale operations. Because laser cutters can reduce production time by cutting materials faster. Fabricators can offer the quickest cutting industry speeds when they employ the proper sort of laser cutter. Laser cutters may also be quite handy for quickly creating prototypes. Laser cutters boost fabrication efficiency by allowing several pieces to be designed and then cut at the same time, in addition to rapid cutting times.

Work Accuracy

Concerning precision, laser cutters are practically unparalleled. CNC routers control the cutters to make intricate geometric patterns out of difficult cuts, and lasers execute these cuts and forms with pinpoint precision. Laser cutters produce smooth edges and a clean finish. Anything that meets the laser is burned, evaporated, or melted. As a result, there will be no additional debris that could result in a rough cut. Not only does this precision results in high-quality components, but it also helps to eliminate waste during the production process. Because laser cutters typically manufacture parts with higher precision, they’re ideal for cutting parts for aerospace and medical device fabrication, where stringent dimensional forbearance and quality requirements are required.

Energy Consumption

A laser cutter’s efficiency, paired with its modern technology, results in it using less energy than conventional cutting processes. Laser cutters, on the other hand, normally use roughly 10kW during each cutting operation, whereas other cutting mechanisms need over 50kW. Laser cutters can assist manufacturers in working smarter and using less energy, as a cost-cutting technique and as an environmentally beneficial one. Laser cutters are an excellent technique to reduce energy consumption in the process of fabrication.

Production Consistency

You can be confident that your components and their assemblies are exact because laser cutters produce such precise cuts. CNC CAD/CAM applications are used to program laser cutters, making sure that the cuts can be made as many times as needed. You may be confident that the cuts will be made exactly as programmed as laser cutting prototyping is incredibly precise. Consistency in every fabrication project is the product of this accuracy and programming. When making several versions of the same article, you can be confident that each one will be identical. You can also rest assured that the laser cutter will create the same high-quality results every time you use it.

Product Versatility

Multi-axis lasers enable laser cutters to assist with a wide range of applications. They can cut a wide range of materials and thicknesses. They can cut both basic and complex structures. Metals, alloys, jewels, polymers, woods, and glass are among the materials that laser cutters can accurately cut. Laser cutters can cut detailed and highly exact forms out of all the materials, including multiple materials at once. Because of their accuracy and precision, laser cutters can make a virtually limitless number of cuts.

More Advantages

When it comes to sheet metal products, laser cutting prototyping has a lot of advantages. Laser cutters can create more intricate designs and edges. In the case of sheet metal prototypes, however, laser cutting allows for quick reaction to modifications, rapid prototyping, shorter lead times, and lower short-run costs. Because of the small size of the laser, it is feasible to create more imaginative and complex designs than in other cutting processes. Laser cutting produces a highly polished edge and eliminates every need to buff away burrs and rough edges. For the fact that there aren`t any blades to be replaced or sharpened, it requires minimal maintenance. Lasers can operate for an extended length of time without supervision. The lack of retooling or modification required by laser cutters allows for rapidly changing the number of pieces that should be made. Part of the principal factors why laser cutters happen to be a popular option for rapid prototyping is this.

Conclusion

Laser cutters make extremely precise cuts, which means fewer finishing steps are required. They also provide edges that are smooth and devoid of burrs. Because the beams are firmly concentrated, there will be no interior faults caused by heat exposure. Quality inspections are less time-consuming with laser cutters since they create high-quality, accurate cuts. They make certain that all part specifications are met, resulting in effective quality checks.

When it comes to metal fabrication, it’s critical to do your homework well. Because not all organizations can produce high-quality work.

Globerdesign services will make your ideas a reality by putting them into action starting with designing and unto production. They provide the services of laser cutting prototyping, metal fabrication, and a complete production process.